Thread breaks are one of the most frustrating problems in embroidery production. Whether you’re running a commercial embroidery business or working on personal projects, constant thread breaks can slow down production, waste materials, and damage your reputation. The good news. Most thread break issues stem from poor digitizing practices rather than machine problems.

In this comprehensive guide, we’ll explore how proper embroidery digitizing techniques can dramatically reduce thread breaks and improve your overall embroidery quality.

Understanding Thread Breaks in Embroidery

Before diving into solutions, it’s important to understand why thread breaks occur. While mechanical issues like improper threading, worn needles, or tension problems can cause breaks, poor digitizing is often the primary culprit.

Thread breaks happen when the thread experiences excessive stress during the stitching process. This stress can result from tight stitches, improper stitch directions, excessive density, or problematic underlay settings in your embroidery design file.

The Connection Between Digitizing and Thread Breaks

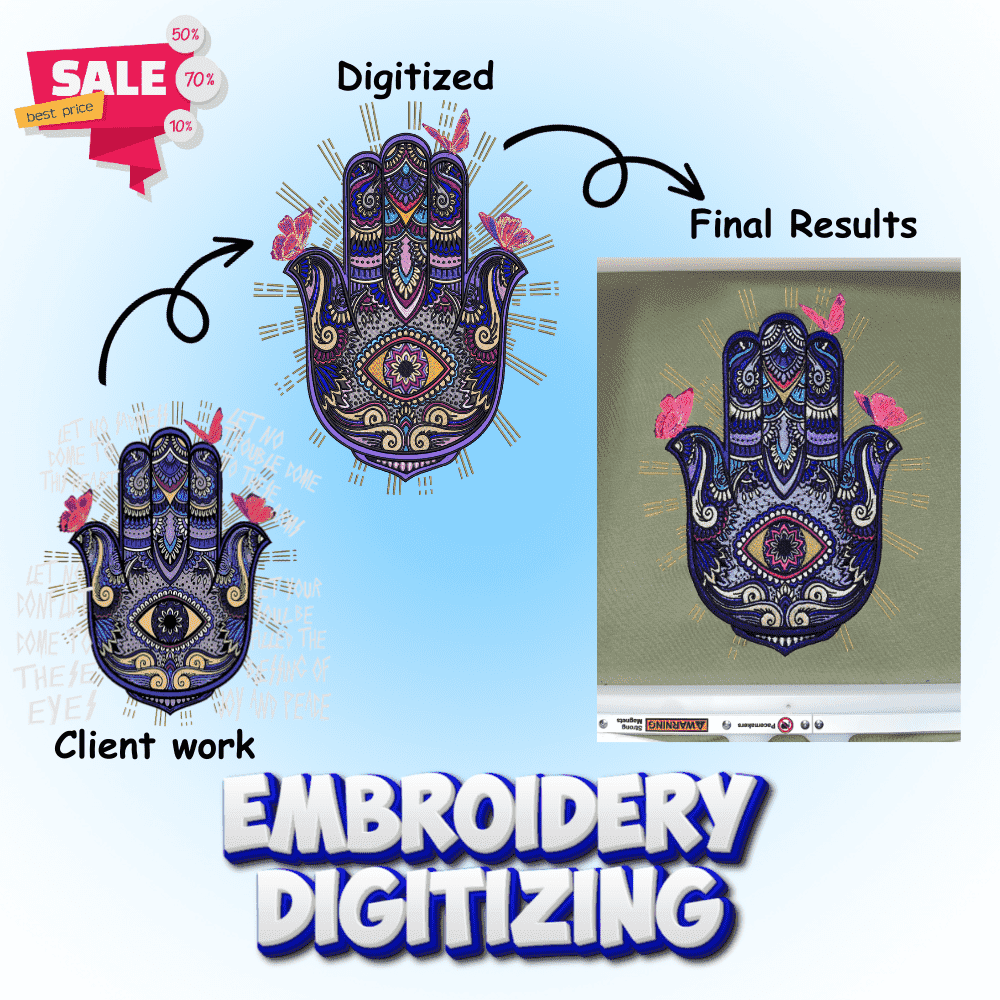

Embroidery digitizing is the process of converting artwork into a stitch file that embroidery machines can read. Quality digitizing takes into account fabric type, thread characteristics, and machine capabilities to create designs that stitch smoothly.

Poor digitizing practices create unnecessary tension on the thread, leading to frequent breaks. By improving your digitizing techniques, you can eliminate most thread break problems at the source.

Key Digitizing Techniques to Prevent Thread Breaks

1. Optimize Stitch Density

One of the most common digitizing mistakes is excessive stitch density. When too many stitches are packed into a small area, the fabric becomes oversaturated, creating resistance that causes threads to break.

Best practices for stitch density:

- Use density settings appropriate for your fabric type (lighter fabrics need less density)

- Avoid overlapping fill areas unnecessarily

- Reduce density in small details where high coverage isn’t essential

- Test different density settings to find the optimal balance for your specific project

Heavy fabrics like denim can handle higher density, while delicate fabrics like silk require lighter coverage. Adjusting your density settings based on fabric weight is crucial for preventing thread breaks.

2. Set Proper Underlay Stitches

Underlay stitches form the foundation of your embroidery design. They stabilize the fabric and provide a base for top stitches to grip. However, improper underlay can actually increase thread breaks.

Underlay best practices:

- Use edge run underlay for satin columns to prevent fabric distortion

- Apply center run underlay for narrow columns

- Implement zigzag or lattice underlay for fill areas on stretchy fabrics

- Avoid excessive underlay that can create too much build-up

- Match underlay direction perpendicular to your top stitch direction for better stability

Proper underlay reduces fabric puckering and provides a stable base that minimizes thread stress during the embroidery process.

3. Manage Pull Compensation Correctly

Pull compensation (also called auto compensation) adjusts design dimensions to account for the natural pulling effect that occurs when stitches are sewn. Without proper pull compensation, designs can distort, creating tension that leads to thread breaks.

Pull compensation guidelines:

- Apply appropriate compensation values based on fabric stretch and stability

- Use higher compensation for stretchy knit fabrics

- Reduce compensation for stable woven fabrics

- Test compensation settings on sample fabrics before production runs

- Adjust compensation differently for satin stitches versus fill stitches

Most digitizing software offers automatic pull compensation, but understanding when and how to adjust these settings manually gives you better control over stitch quality.

4. Control Stitch Direction and Angles

The direction of your stitches significantly impacts thread tension and break frequency. Stitches that fight against fabric grain or create excessive friction are more prone to breaking.

Stitch direction strategies:

- Align satin stitches perpendicular to the element’s direction for strength

- Use varying stitch angles in large fill areas to prevent stitch buildup

- Create smooth transitions between different stitch directions

- Avoid sudden direction changes that create stress points

- Consider fabric nap and grain when setting stitch angles

Strategic stitch direction placement distributes tension more evenly across your design, reducing the likelihood of thread breaks.

5. Optimize Satin Stitch Width

Satin stitches that are too wide become unstable and prone to thread breaks. The maximum recommended width varies depending on fabric type and stabilizer used.

Satin stitch width recommendations:

- Keep satin columns between 4-6mm width for most applications

- Use split techniques for wider elements, dividing them into multiple narrower columns

- Apply underlay for satin columns wider than 4mm

- Consider using fill stitches instead of satin for very wide areas

- Test different widths on your specific fabric and stabilizer combination

Narrow, well-digitized satin stitches stitch more reliably and create cleaner edges with fewer thread breaks.

6. Reduce Jump Stitches and Trims

Excessive jump stitches and trim commands create unnecessary machine movement and increase the chances of thread breaks, especially when the machine restarts after a trim.

Jump stitch optimization:

- Minimize color changes by optimizing stitch sequence

- Use traveling stitches instead of jumps when possible

- Connect nearby elements with running stitches to reduce jumps

- Set appropriate jump stitch length in your digitizing software

- Review and manually edit trim commands to reduce unnecessary cuts

Reducing jumps and trims not only decreases thread breaks but also improves production efficiency.

7. Add Proper Start and End Points

How a design starts and ends can significantly impact thread stability. Proper tie-in and tie-off stitches prevent loose threads and reduce breaks at the beginning and end of elements.

Start and end point techniques:

- Use adequate tie-in stitches (typically 3-4 small stitches) at the beginning of each element

- Apply proper tie-off stitches before trims

- Avoid starting stitches in high-stress areas

- Position start points in areas that will be covered by subsequent stitches

- Ensure smooth transitions between connected elements

Well-placed start and end points create secure stitching that withstands production stress.

8. Consider Fabric Type in Your Digitizing

Different fabrics require different digitizing approaches. What works perfectly on cotton might cause constant thread breaks on polyester fleece or stretchy athletic wear.

Fabric-specific digitizing considerations:

- Reduce density and use more underlay for stretchy fabrics

- Increase density slightly for loosely woven fabrics that need better coverage

- Use push compensation for pile fabrics like towels and fleece

- Apply lighter touch for delicate fabrics to prevent damage

- Test designs on actual production fabric before full runs

Adapting your digitizing techniques to match your fabric characteristics is essential for preventing thread breaks.

Advanced Digitizing Strategies for Thread Break Prevention

Use Proper Digitizing Software

Professional embroidery digitizing software offers advanced features that help prevent thread breaks. Programs like Wilcom, Pulse, and Hatch provide precise control over stitch parameters.

Quality software allows you to:

- Set precise density and underlay parameters

- Visualize stitch direction and potential problem areas

- Simulate the embroidery process before production

- Make micro-adjustments to individual elements

- Access stitch editing tools for fine-tuning designs

Investing in quality digitizing software pays dividends through reduced thread breaks and better overall embroidery quality.

Implement Gradient Density

For designs with varying coverage needs, gradient density creates smooth transitions that reduce stress points where thread breaks often occur.

This technique gradually adjusts density across an element rather than using uniform density throughout. Gradient density is particularly useful for photorealistic embroidery and designs with shading effects.

Apply Stitch Length Optimization

Shorter stitches create more thread penetrations and can increase friction and heat buildup, leading to breaks. Longer stitches may skip or create loose embroidery.

The optimal stitch length for most fill stitches is between 3-4mm. For satin stitches, the length varies based on width but should create smooth coverage without excessive penetrations.

Use Appropriate Pathing and Sequencing

The order in which elements stitch affects overall design stability and thread break frequency. Proper sequencing ensures that:

- Underlay stitches before top stitches

- Interior elements stitch before border elements

- Large areas stitch before small details

- Connected elements stitch in logical progression

Strategic sequencing reduces unnecessary thread movement and creates better fabric stability throughout the embroidery process.

Testing and Quality Control

Even with perfect digitizing techniques, testing is essential. Before running production, always:

Create test runs on actual production fabric with the same stabilizer and thread you’ll use for the final product. Watch for thread breaks and note where they occur.

Make incremental adjustments rather than changing multiple parameters at once. This helps you identify which specific change resolves the thread break issue.

Document your settings for different fabric types so you can replicate successful digitizing parameters for future projects.

Maintain a sample library of successfully stitched designs with notes on fabric type, stabilizer, tension settings, and digitizing parameters used.

Common Digitizing Mistakes That Cause Thread Breaks

Avoiding these common errors will significantly reduce your thread break problems:

Over-digitizing designs with too much detail for the size and fabric creates excessive density and tension. Simplify designs when necessary rather than trying to include every tiny detail.

Ignoring minimum stitch lengths causes excessive needle penetrations and friction. Respect the limitations of your machine and fabric.

Using default settings for all projects without adjusting for specific fabric and thread combinations leads to inconsistent results.

Neglecting to clean up automatically generated stitches leaves inefficient pathing and unnecessary jump stitches that increase break frequency.

Failing to consider hooping direction relative to fabric grain creates additional stress on stitches.

Complementary Factors Beyond Digitizing

While proper digitizing eliminates most thread break causes, these complementary factors also play important roles:

Use quality embroidery thread that’s appropriate for your machine type and fabric. Bargain thread often has weak spots and inconsistencies that cause breaks regardless of digitizing quality.

Maintain your embroidery machine with regular cleaning, oiling, and replacement of worn parts like needles and rotary hooks.

Select the appropriate stabilizer for your fabric type and design density. Inadequate stabilization causes fabric distortion that increases thread stress.

Check thread tension settings on your machine. Tension that’s too tight causes obvious thread breaks, while tension that’s too loose creates looping and bird nesting.

Monitor needle condition and replace needles regularly. Dull or damaged needles create friction and heat that weakens thread.

FAQs

Q1: What is the main cause of thread breaks in embroidery?

Poor digitizing practices like excessive density, improper underlay, and incorrect pull compensation create thread tension that causes breaks.

Q2: What is the ideal stitch density to prevent thread breaks?

Use 4-5mm spacing for light fabrics and 3-4mm for heavy fabrics, avoiding over-saturation.

Q3: How wide should satin stitches be to avoid thread breaks?

Keep satin columns between 4-6mm width; split wider elements into multiple narrow columns.

Q4: What is pull compensation and why does it matter?

Pull compensation adjusts design dimensions to prevent fabric distortion and reduce thread tension.

Q5: How does underlay prevent thread breaks?

Underlay stabilizes fabric and provides a foundation that prevents distortion and reduces thread stress.

Q6: Can thread breaks be caused by fabric type?

Yes, different fabrics need different digitizing approaches for density, underlay, and compensation settings.

Q7: What’s the optimal stitch length for fill stitches?

The ideal stitch length is 3-4mm for good coverage without excessive friction.

Q8: How do jump stitches contribute to thread breaks?

Excessive jumps and trims create unnecessary machine movement and increase break chances during restarts.

Q9: Should I use the same digitizing settings for all fabrics?

No, adjust density, underlay, pull compensation, and stitch length based on each fabric type.

Q10: How can I test if my digitizing will cause thread breaks?

Run test stitchouts on actual production fabric with the same stabilizer and thread before full production.

Conclusion

Thread breaks in embroidery can be largely prevented through improved digitizing practices, including optimizing stitch density, using proper underlay, managing pull compensation, and controlling stitch direction.

Successful digitizing combines technical understanding with design aesthetics. By implementing these techniques and refining them based on real-world results, embroidery production quality can improve, leading to fewer thread breaks and enhanced customer satisfaction.