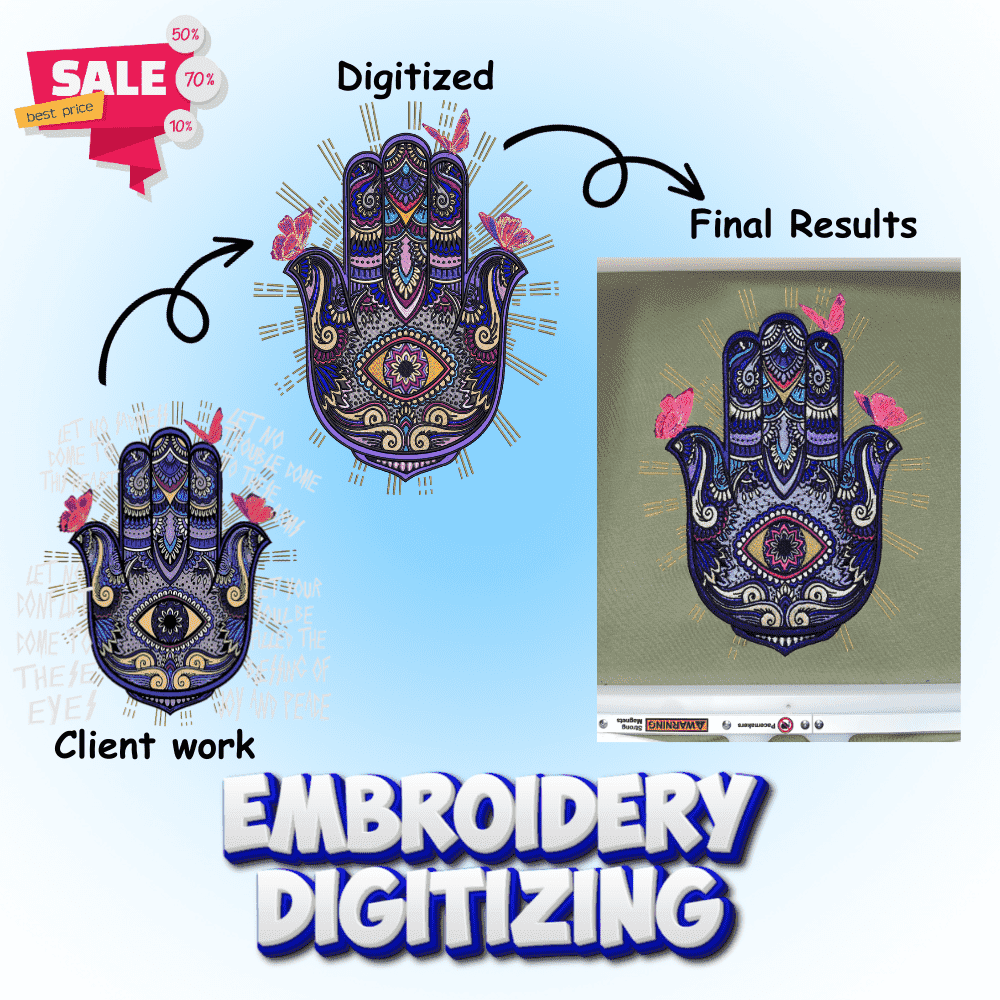

3D puff embroidery digitizing is a specialized embroidery technique that transforms flat designs into eye-catching, dimensional artwork. This technique has become increasingly popular for caps, hats, jackets, and promotional items, offering a premium, professional appearance that standard embroidery simply cannot match.

Whether you’re starting an embroidery business, looking to expand your services, or simply want to create unique personalized items, understanding 3D puff embroidery digitizing is essential. This comprehensive guide will walk you through everything from the basics to advanced techniques, helping you create professional-quality raised designs.

What is 3D Puff Embroidery?

3D puff embroidery is a specialized embroidery technique that uses a special foam material placed underneath stitches to create a raised, three-dimensional effect. Unlike traditional flat embroidery, this method literally makes your designs “pop” from the fabric surface, creating bold, attention-grabbing text and graphics.

The process involves placing embroidery foam on top of the fabric before stitching. As the needle penetrates the foam, it creates perforations. After the embroidery is complete, the excess foam is torn away, leaving only the foam beneath the stitched area, which creates the distinctive raised effect.

Regular Embroidery vs 3D Puff Embroidery

Regular Embroidery:

- Stitches applied directly to fabric

- Flat, two-dimensional appearance

- No additional thickness

- Simpler and quicker process

- Suitable for detailed designs

3D Puff Embroidery:

- Foam layer creates dimension

- Raised, three-dimensional effect

- Bold, eye-catching appearance

- Professional, premium look

- Best for simple, bold designs

The 3D Puff Embroidery Digitizing Process

Step 1: Design Selection and Preparation

Not all designs are suitable for 3D puff embroidery. Choosing the right design is crucial for success.

Ideal Designs for 3D Puff:

- Bold text and letters (wider than 5mm)

- Simple logos with solid shapes

- Mascots and character outlines

- Team names and numbers

- Block letters and geometric designs

- Brand names and emblems

Designs to Avoid:

- Intricate details and fine lines

- Very small text (less than 5mm)

- Complex gradients and shading

- Photorealistic images

- Thin, delicate elements

- Detailed illustrations

Step 2: Choosing Digitizing Software

Professional 3D puff embroidery requires specialized software with specific capabilities.

Top Embroidery Digitizing Software:

- Wilcom Embroidery Studio – The industry standard with comprehensive 3D puff features, advanced editing tools, and professional-grade output. Ideal for commercial operations.

- Hatch Embroidery – User-friendly interface perfect for beginners, with 30-day free trial. Offers excellent tutorials and customer support.

- Brother PE-Design – Best for Brother machine users, affordable, and includes specific puff embroidery fonts and templates.

- Embird – Cost-effective option with good capabilities, modular system allows you to buy only what you need.

- DesignShop v11 – Professional-grade software with specialized puff fonts and precise control over stitch parameters.

Step 3: Critical Digitizing Settings for 3D Puff

This is where many beginners make mistakes. Proper settings are absolutely essential for successful 3D puff embroidery.

Stitch Density:

- 3D puff requires stitch spacing of 0.16mm to 0.22mm

- Regular embroidery typically uses 0.36mm spacing

- Denser stitching properly cuts and covers the foam

- Ensures foam tears away cleanly after embroidery

- Creates crisp, professional edges

Satin Stitch Width:

- Minimum width: 5-7mm (narrower won’t work well)

- Maximum width: 10-12mm

- For thicker foam (4-6mm): use wider stitches (7-10mm)

- For thinner foam (2mm): 5-6mm is sufficient

- Width affects the dimensional appearance

Underlay Stitching:

- Traditional underlay should be AVOIDED

- Underlay compresses the foam, defeating the purpose

- Use only tack-down stitches if necessary

- Center walk stitch with 4mm length works well

- Minimal underlay preserves foam height

End Capping:

- Satin columns require capping stitches at ends

- These hold the foam down and prevent sticking out

- Critical for clean, professional appearance

- Prevents foam edges from fraying

- Creates defined boundaries

Step 4: Software-Specific Settings Adjustments

Settings to Disable:

- Auto-split features (creates unwanted breaks)

- Smart corners (can compress foam)

- Fractional spacing

- Automatic underlay generation

- Stitch shortening features

Settings to Enable:

- Manual underlay control

- End cap stitching

- Pull compensation (increase by 0.3-0.5mm)

- Custom density controls

- Precise stitch angle control

Essential Materials for 3D Puff Embroidery

1. Embroidery Foam (Puff Foam)

The foundation of 3D embroidery is the foam itself. Quality matters significantly.

Thickness Options:

- 2mm Foam: Provides subtle effects, ideal for smaller designs and delicate applications. Good for beginners to practice.

- 3mm Foam: The most popular standard thickness, offering excellent balance between height and manageability. Used in 80% of commercial applications.

- 4mm Foam: Medium-high effect, perfect for bold statements. Popular for sports team logos.

- 6mm Foam: Maximum dimension for dramatic impact. Best for large, bold designs on caps.

Color Selection: Always match foam color as closely as possible to your thread color. If stitches slightly miss or gap, the foam won’t show through. White foam works well with light colors, black with dark colors.

Foam Quality Types:

- Embroidery-Grade Foam: Dense, consistent thickness, clean tear-away properties. Worth the investment for professional work.

- Craft Store Foam: Budget option, may require layering for desired thickness. Good for practice and personal projects.

Recommended Brands:

- PuffyStitch (excellent consistency)

- Gunold E-Zee 3D Foam (widely available)

- AllStitch Puffy Foam (affordable quality)

- Madeira 3D Foam (premium option)

2. Thread Selection

Thread choice significantly impacts the success and durability of 3D puff embroidery.

Best Thread Type: Polyester

- Superior strength and durability

- Fewer thread breaks with dense stitching

- Handles the stress of foam thickness

- Excellent color retention

- Washing machine stable

- Commercial-grade quality

Alternative: Rayon

- Beautiful glossy finish

- Higher risk of thread breaks

- Better for decorative, less-washed items

- Requires slower machine speed

Metallic Thread:

- Creates special effects and accents

- Use polyester-core metallic for stability

- Requires even slower speed

- Best combined with polyester for main stitching

Thread Weight:

40-weight thread is standard and works best for most applications.

3. Stabilizers

Proper stabilization is crucial for quality 3D puff embroidery.

For Caps and Hats:

Use tear-away stabilizer

- Caps have inherent stiffness

- Easy removal after embroidery

- Doesn’t need to withstand heavy washing

- Medium to heavyweight tear-away

For Garments:

Use cutaway mesh stabilizer

- Provides long-term support

- Essential for machine-washable items

- “If you wear it, don’t tear it” rule applies

- Remains permanently in garment

Stabilizer Weight:

- Medium weight for light to medium fabrics

- Heavyweight for maximum support on heavy items

- Multiple layers if needed for problem fabrics

4. Needles

The right needle makes a significant difference.

Recommended Specifications:

- Size: 75/11 or 90/14

- Sharp point needles (not ballpoint)

- KK needles (shorter shank, longer blade) ideal

- Embroidery-specific needles

- Change needles regularly (every 8-10 hours)

Larger needles handle the foam thickness better and reduce needle deflection.

Machine Settings and Embroidery Process

Machine Setup

Presser Foot Height:

- Raise 6-9 clicks above normal position

- Accommodates foam thickness

- Prevents compression during stitching

- Check machine manual for specific instructions

Thread Tension:

- Slightly loosen top thread tension

- Adjust for foam’s extra thickness

- Test on scrap material first

- Fine-tune based on results

Embroidery Speed:

- Reduce by 25-40% from normal speed

- Approximately 400-600 stitches per minute

- Slower speed = better quality

- Prevents thread breaks and skipped stitches

Embroidery Sequence

Step-by-Step Process:

- Hoop Preparation: Properly hoop garment with appropriate stabilizer

- Base Embroidery: Stitch the outline or tack-down stitches first

- Machine Stop: Program should include stop code after outline

- Foam Placement: Carefully position foam sheet over outlined area

- Secure Foam: Use temporary adhesive spray on corners (optional but helpful)

- Resume Stitching: Complete the 3D puff section

- Finish Design: Complete any additional elements

- Remove Hoop: Carefully remove finished piece

Testing and Quality Control

Always Test First:

- Use scrap fabric of the same type

- Same thickness and weave

- Check tension, density, and alignment

- Adjust settings before final production

- Keep test samples for reference

Common Problems and Solutions

Foam Showing Through Stitches

Causes:

- Insufficient stitch density

- Gaps in coverage

- Wrong thread color

Solutions:

- Increase stitch density to 0.16mm spacing

- Use thread color matching foam

- Check for skipped stitches

- Re-digitize with tighter spacing

Uneven Height or “Flat” Areas

Causes:

- Inconsistent foam thickness

- Presser foot too low

- Accidental compression

Solutions:

- Use consistent, quality foam

- Raise presser foot adequately

- Check for underlay issues

- Ensure even stitching throughout

Design Distortion or Puckering

Causes:

- Inadequate pull compensation

- Poor stabilization

- Foam too thick for design

Solutions:

- Increase pull compensation to 0.3-0.5mm

- Use stronger stabilizer

- Test on similar fabric first

- Consider thinner foam

Excessive Thread Breaks

Causes:

- Thread tension too tight

- Speed too fast

- Wrong thread type

- Dull needle

Solutions:

- Adjust thread tension (loosen slightly)

- Use polyester thread

- Reduce machine speed

- Replace needle with larger size

- Check thread path for snags

Foam Not Tearing Cleanly

Causes:

- Stitch spacing too wide

- Poor quality foam

- Missing end caps

Solutions:

- Tighten stitch spacing to 0.16mm

- Use embroidery-grade foam

- Add proper end cap stitches

- Re-digitize design if necessary

Registration Issues

Causes:

- Foam shifting during embroidery

- Inadequate securing

- Design too complex

Solutions:

- Use temporary adhesive spray

- Simplify design elements

- Add more tack-down stitches

- Ensure proper hooping tension

Finishing Touches and Care

Foam Removal Process

Step-by-Step:

- Gently tear away excess foam from around design

- Foam should tear cleanly along stitch lines

- Use tweezers for small remaining pieces

- For stubborn bits, use low heat gun carefully

- Be cautious with polyester thread (can melt)

- Brush away any foam remnants

Tips:

- Tear away from the design, not toward it

- Work slowly and carefully

- Some tiny foam bits may remain (normal)

- Don’t pull aggressively (can damage stitches)

Care Instructions

Machine Washing:

- 3D puff foam is machine washable

- Use gentle or normal cycle

- Avoid excessive washing for longer lifespan

- Turn garments inside out for protection

Drying:

- Machine dry on low to medium heat

- Avoid over-drying

- Air drying is gentlest option

- Don’t iron directly on 3D puff

Never:

- Dry clean (foam is flammable)

- Apply direct high heat

- Use bleach on colored foam

- Wring or twist forcefully

Applications of 3D Puff Embroidery

1. Baseball Caps and Hats

The most popular application, accounting for 70% of 3D puff work:

- Team logos and emblems

- Brand names

- Numbers and player names

- Mascot designs

- Company branding

2. Jackets and Outerwear

Premium appearance for:

- Back panel designs

- Chest logos

- Sleeve graphics

- Letter jackets

- Corporate branding

3. Bags and Backpacks

Durable branding for:

- School bags

- Gym bags

- Corporate gifts

- Promotional items

4. Promotional Merchandise

High-impact branding:

- Trade show giveaways

- Corporate events

- Team building items

- Fundraising products

5. Custom Apparel

On heavyweight fabrics:

- Hoodies and sweatshirts

- Heavyweight t-shirts

- Work shirts

- Team uniforms

Business Perspective: Pricing and Profitability

Cost Analysis

Per Item Cost Breakdown (Baseball Cap Example):

- Embroidery foam: $0.25-$0.50

- Thread and supplies: $0.50-$1.00

- Embroidery time: 10-15 minutes

- Labor and overhead: $2.00-$3.00

- Total cost per cap: $3-$5

Pricing Strategy

Retail Pricing:

- Regular embroidered cap: $12-$15

- 3D puff embroidered cap: $18-$25

- Premium custom designs: $25-$35

- Corporate orders (bulk): $15-$22 per piece

Profit Margins:

- Standard job: 60-70% margin

- Bulk orders: 50-60% margin

- Custom one-offs: 70-80% margin

Example Calculation:

- 60-cap order @ $20 each = $1,200 revenue

- Total production cost = $300-$400

- Net profit = $800-$900

- Production time = 10-16 hours

- Excellent ROI for small businesses

Market Positioning

3D puff embroidery allows you to:

- Command premium pricing

- Differentiate from competitors

- Attract corporate clients

- Build a specialty niche

- Create memorable products

Advanced Techniques

Multi-Layer Puff Effects

Create complex dimensions by:

- Using different foam thicknesses in one design

- Layering foam for extra height

- Combining 2mm and 4mm in same design

- Creating depth hierarchy

- Adding visual interest

Combined Techniques

3D Puff + Applique:

- Applique fabric pieces first

- Add 3D puff elements on top

- Creates rich, textured designs

- Premium appearance

3D Puff + Chenille:

- Mix soft chenille with puff

- Different texture contrasts

- Unique visual appeal

- Varsity jacket style

3D Puff + Standard Embroidery:

- Outline in standard flat embroidery

- Fill with 3D puff

- Adds definition and contrast

- Professional finish

Color Contrast Techniques

Outline in Different Color:

- Main design in 3D puff

- Outline in contrasting flat embroidery

- Creates defined borders

- Adds visual pop

Multi-Color Puff:

- Different sections in different colors

- Each color requires separate foam placement

- More complex but stunning results

- Premium pricing justified

Expert Tips for Success

1. Always Match Foam Color to Thread

This is the single most important tip. If your thread slightly misses or gaps appear, matching foam color saves the design.

2. Start with Simple Designs

Practice with basic text and simple logos before attempting complex designs. Build your skills progressively.

3. Invest in Quality Materials

Good foam and thread make the difference between amateur and professional results. Don’t cut corners on materials.

4. Slow and Steady Wins

Resist the urge to run at full speed. Quality results come from patience and proper speed.

5. Save Your Successful Settings

Create templates for different fabric types, foam thicknesses, and design styles. Build your knowledge library.

6. Join Online Communities

Forums, Facebook groups, and YouTube channels provide invaluable tips, troubleshooting help, and inspiration.

7. Keep Software Updated

Regular updates include bug fixes, new features, and improved functionality. Stay current.

8. Consider Professional Digitizing

For complex logos or critical projects, professional digitizers can save time and ensure perfect results.

9. Document Everything

Keep records of successful settings, foam types, thread colors, and machine parameters. Build your reference library.

10. Practice, Practice, Practice

Every machine, fabric, and design combination is slightly different. Experience is the best teacher.

DIY vs Professional Digitizing Services

DIY Approach

Advantages:

- Complete creative control

- Cost savings on ongoing projects

- Valuable learning experience

- Flexibility in timing

- Skill development

- Independence

Disadvantages:

- Steep learning curve

- Initial software investment ($200-$2,000)

- Time-consuming initially

- Trial and error process

- Equipment requirements

- Technical knowledge needed

Professional Digitizing Services

Advantages:

- Expert-quality results guaranteed

- Significant time savings

- Consistent, reliable output

- Access to advanced equipment

- Efficient for bulk orders

- No learning curve needed

Disadvantages:

- Recurring costs ($10-$50 per design)

- Less personal control

- Turnaround time dependency

- Communication challenges

- May need revisions

- Ongoing expense

When to Use Each:

- DIY for ongoing business with regular designs

- Professional for one-off complex logos

- DIY for learning and skill building

- Professional when time is critical

Future of 3D Puff Embroidery

Emerging Technologies

AI-Powered Digitizing:

- Automated density optimization

- Smart underlay generation

- Intelligent foam thickness recommendations

- Reduced setup time

Enhanced Software Features:

- Real-time 3D preview

- Automatic problem detection

- Cloud-based collaboration

- Mobile app integration

Material Innovations:

- More color options in foam

- Eco-friendly foam materials

- Improved washability

- Enhanced durability

Market Trends

Growing Demand:

- Increased customization requests

- Premium branding focus

- Home embroidery market expansion

- Social media influence

Sustainable Materials:

- Biodegradable foam development

- Recycled thread options

- Eco-conscious consumers

- Green manufacturing

Technology Integration:

- Direct-to-garment integration

- Automated production systems

- Online design tools

- Virtual try-on technology

FAQs

1. What foam thickness is best for 3D puff embroidery?

The most commonly used thickness is 3mm foam, which provides an excellent balance between visibility and manageability.

2. Can I use a regular embroidery design for 3D puff?

No, you cannot use regular embroidery designs for 3D puff without modifications.

3. How long does 3D puff embroidery last?

With proper care, 3D puff embroidery is extremely durable and can last for years.

4. Which digitizing software is best for beginners?

Hatch Embroidery is excellent for beginners due to its user-friendly interface, comprehensive tutorials, and 30-day free trial.

5. What is the average cost of 3D puff embroidery?

Material costs per design are approximately $2-$5 (including foam, thread, stabilizer, and overhead)

6. Can 3D puff embroidery be done on thin fabrics?

While possible, it’s not recommended. 3D puff embroidery works best on heavyweight fabrics like canvas, twill, denim, felt, and sturdy knits.

7. How do I safely remove excess foam after embroidery?

After embroidery is complete, gently tear away excess foam from around the design. The dense stitching creates perforations that allow the foam to tear cleanly.

8. What machine speed should I use for 3D puff embroidery?

Reduce your normal embroidery speed by 25-40%. A speed of approximately 400-600 stitches per minute is ideal for most 3D puff applications.

9. Is polyester thread necessary, or can I use rayon?

Polyester thread is highly recommended and considered industry standard for 3D puff embroidery. Rayon thread can be used for its beautiful glossy finish, but it breaks more easily, requiring slower speeds.

10. How can I make 3D puff embroidery profitable for my business?

Focus on quality over quantity and position yourself as a premium provider.

Conclusion

3D puff embroidery digitizing is a specialized skill that can significantly enhance your embroidery services and move you into the premium market. With practice, proper technique, and attention to detail, you can achieve stunning results that impress clients and justify premium pricing.

Start simple, invest in quality materials, and continuously refine your skills. The dimensional, eye-catching results are well worth the effort and learning curve!